The demand for effective cell culture equipment continues to grow, driven by advancements in biotechnology and pharmaceuticals. A recent report from Research and Markets reveals that the global cell culture market is expected to reach $21.75 billion by 2027. This considerable growth highlights the importance of investing in high-quality tools for optimal lab success.

Choosing the right cell culture equipment is crucial for researchers. Modern laboratories must ensure the reliability and accuracy of their results. Essential equipment includes incubators, biosafety cabinets, and bioreactors. Each piece plays a vital role in the cell growth process, impacting experimental outcomes. However, many labs still rely on outdated equipment, which can lead to inconsistencies and unreliable data.

Investing in advanced cell culture technology can enhance productivity. For instance, automated cell counters provide precise measurements that manual methods cannot match. Yet, despite these innovations, some researchers face challenges in adapting to new technologies. This indeed invites reflection on balancing cost and quality in lab equipment choices. Upgraded cell culture equipment is not just an asset; it is a foundation for scientific breakthroughs.

Selecting the right cell culture equipment is essential for any lab aiming for success. Key factors include the equipment's design, functionality, and ease of use. A well-designed incubator, for instance, maintains stable temperature and humidity levels, which are crucial for cell health. Stability can improve cell yield by up to 30%, according to recent industry reports.

Budget constraints pose a significant challenge. Cutting costs might lead to subpar equipment that affects results. A report showed that labs that didn't invest in quality saw a 25% decrease in reproducible results. Moreover, the ease of cleaning and maintenance cannot be overlooked. Frequent equipment failures can disrupt experiments and delay results. It is vital to consider these aspects when choosing equipment, though such reflections often reveal gaps in foresight.

Training is another crucial consideration. Lab personnel must be skilled in using the equipment efficiently. Insufficient training can lead to errors, affecting overall productivity. Industry surveys indicate that 40% of labs struggle with operational inefficiencies due to underqualified staff. The choice of cell culture equipment influences not only results but also workflow and team performance.

Cell culture is a cornerstone of modern biomedical research. Essential types of cell culture equipment play a crucial role in fostering optimal laboratory conditions. According to industry reports, incubators provide a controlled environment for cell growth. They typically maintain a temperature of 37°C and 5% CO2. These conditions support the majority of mammalian cell lines.

Another vital tool is the biosafety cabinet. This equipment protects both the cultures and the user from contamination. It is critical to maintain sterility during various procedures. Studies highlight that poorly maintained cabinets can lead to increased contamination rates, compromising research outcomes. This emphasizes the need for regular maintenance checks and certifications.

Moreover, size and space can present challenges. Many labs face constraints that force them to choose between essential equipment or dispose of underused items. Selecting multifunctional equipment can alleviate space issues while enhancing efficiency. However, labs often overlook the necessity of regularly evaluating their equipment needs. In conclusion, establishing an optimal cell culture environment demands thoughtful selection of essential tools.

| Equipment Type | Description | Key Features | Typical Uses |

|---|---|---|---|

| Incubator | Provides a controlled environment for growing cell cultures | Temperature control, Humidity control, CO2 regulation | General cell culture, Microbial culture |

| Laminar Flow Hood | Protects samples and operators from contamination | Vertical or horizontal airflow, HEPA filters | Cell manipulation, Aseptic technique |

| Centrifuge | Separates components of a sample based on density | Variable speed settings, Rotor options | Cell separation, Harvesting cells |

| Bioreactor | Used for growing and sustaining cell cultures on a larger scale | Control of pH, Temperature, and nutrient supply | Production of biopharmaceuticals, Tissue engineering |

| Cryopreservation Unit | Freezes and stores cells for long-term preservation | Controlled cooling rates, Liquid nitrogen compatibility | Cell storage, Sample backup |

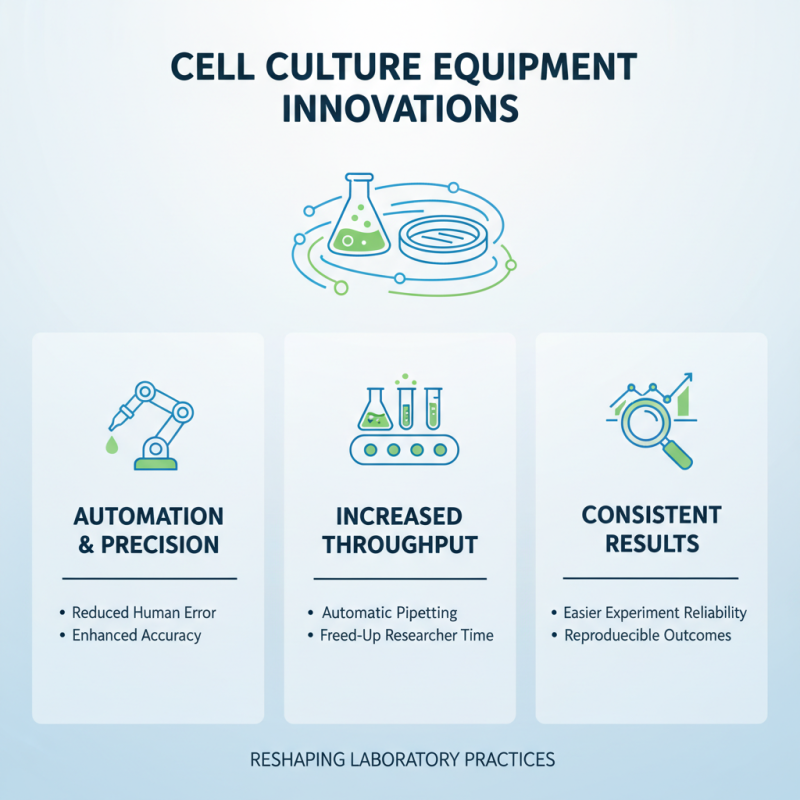

Innovative technologies in cell culture equipment design are reshaping laboratory practices. New automation features enhance precision and reduce human error. Automatic pipetting systems increase throughput and free up valuable researcher time. These tools make it easier to achieve consistent results in experiments.

Another advancement is the use of smart sensors. These sensors monitor environmental conditions, like temperature and pH levels, in real-time. With accurate data, researchers can quickly adjust conditions to optimize cell growth. However, relying too much on technology can pose challenges. Sensors may fail or provide inaccurate readings, leading to compromised experiments.

Finally, modular designs are gaining popularity. Equipment can be tailored to specific research needs, which maximizes laboratory space. Yet, the flexibility of custom setups can lead to complexity. Maintaining various components can be time-consuming. This balance between innovation and practicality needs careful consideration.

Maintaining cell culture equipment is critical for reliable lab results. Regular cleaning and calibration prevent contamination and ensure accurate data. A recent report showed that 30% of lab contamination is due to improper maintenance of equipment. Failing to check incubator temperature can lead to cell death. This may seem minor, but it can ruin months of research.

Proper sterilization techniques are essential. Using autoclaves, for instance, should be part of the routine. Studies indicate that 60% of labs don’t follow strict sterilization protocols. This negligence can compromise experiments. Researchers must also keep an eye on CO2 levels. Inadequate CO2 can disturb the pH balance in cultures.

Documentation is another area needing improvement. Many labs fail to log equipment performance adequately. This oversight makes troubleshooting difficult. An industry survey revealed that 40% of researchers depend on memory rather than records. This can lead to repeated mistakes. Regular training on best practices can help improve the situation. Respecting these guidelines will significantly enhance lab success.

Investing in cell culture equipment can significantly influence laboratory outcomes. A recent industry report shows that the global cell culture market is projected to reach USD 28 billion by 2026. This projection highlights the growing importance of cell culture in research and biotechnology. Evaluating the cost-effectiveness of these investments is crucial.

Cost analysis must include both upfront and ongoing expenses. Equipment like bioreactors and incubators are essential, yet they often require maintenance. A study indicated that 15-20% of budgets may go to equipment upkeep. This raises questions: Are laboratories overspending? Are they prioritizing their investments correctly? It’s essential to reassess equipment choices periodically to align with current research needs.

Data also suggest that underutilization is common. Many labs purchase high-end equipment, only to use a fraction of its capabilities. This waste can equate to thousands of dollars wasted every year. Addressing this issue involves training staff and ensuring that every piece of equipment serves a clear purpose. Balancing the initial investment with practical use is key for maximizing laboratory success.